Are you torn between Direct-to-Garment (DTG) and Direct-to-Film (DTF) printing for your clothing line? With both technologies offering impressive capabilities, it can be tough to decide which method is the best fit for your needs.

These two methods have revolutionized the custom printing industry, each transforming the way businesses print designs on textiles and a variety of other materials. Whether you’re just starting or looking to upgrade your current setup, understanding the differences between DTG and DTF is essential. Each method comes with unique advantages that align with different business needs—whether it’s print volume, material type, or customization requirements.In this article, we’ll explore the key differences, benefits, and limitations of DTG and DTF printing to help you make an informed decision about which one will elevate your clothing line.

What Everybody Ought to Know About DTF and DTG

What is DTG Printing?

Direct-to-garment (DTG) printing uses an inkjet printer to print designs directly onto fabric. It’s similar to the way a traditional inkjet printer works on paper, but here the ink is applied to the fabric rather than paper. The design is printed onto the fabric layer by layer, where the ink is absorbed into the fibers, creating soft, vibrant prints.

What is DTF Printing?

Direct-to-film (DTF) printing, on the other hand, involves printing a design onto a special film that is then heat-pressed onto the fabric. DTF uses a combination of transfer film and adhesive powder to ensure the design sticks to a variety of materials. Once the print is completed on the film, the adhesive powder is applied, and the print is transferred to the fabric using a heat press.

Applications of DTG and DTF

DTG Applications

- Custom Apparel: Ideal for custom T-shirts, hoodies, and other cotton-based garments. Great for short runs, on-demand printing, and personalized products.

- Intricate Designs: Perfect for designs that feature fine details, gradients, and vibrant colors, as DTG can handle complex prints with ease.

- Small-Batch Printing: Because of its quick setup and ease of use, DTG is often used for limited-edition or low-volume runs, making it a great option for clothing line with a focus on customization.

DTF Applications

- Versatile Apparel: DTF works well on cotton, polyester, and blends, making it an excellent choice for a wide range of apparel, from casual wear to sportswear.

- Hard Goods: DTF is also popular for printing on hard surfaces like mugs, phone cases, bags, and even wood or metal items.

- Bulk Orders: With its faster production speed and lower per-print costs, DTF is ideal for larger production runs, especially when fulfilling bulk orders with simple designs.

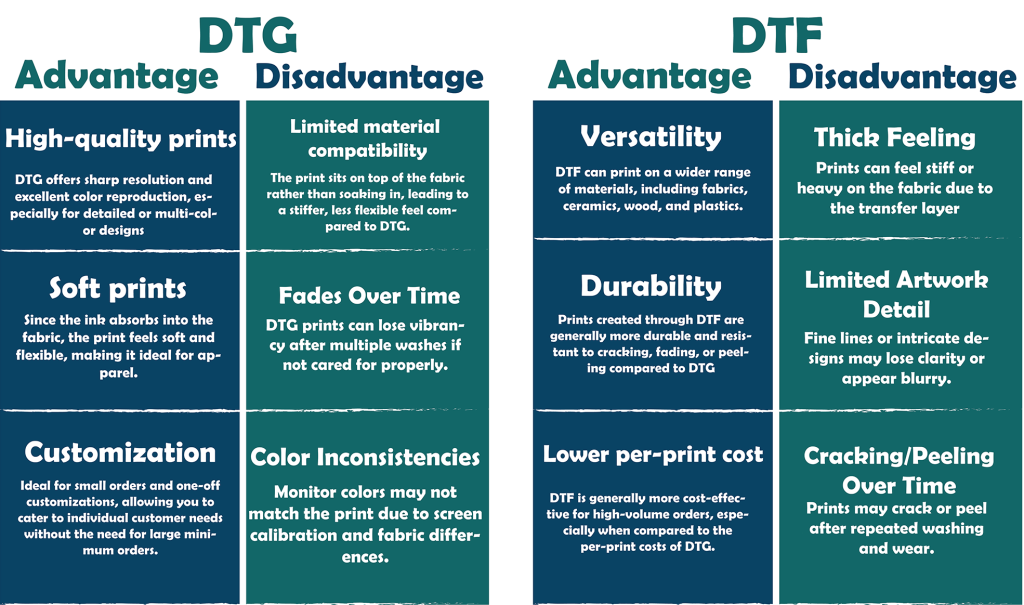

Durability & Color Vibrancy

Print Durability

- DTG: The ink used in DTG printing is absorbed into the fabric, making it durable but susceptible to fading over time, especially after frequent washes.

- DTF: DTF prints tend to be more durable than DTG prints. The design is pressed onto the fabric with adhesive, resulting in stronger adhesion, greater wash resistance, and better overall longevity.

Color Vibrancy

- DTG: The ability to print highly detailed and vibrant designs is one of DTG’s biggest strengths. The colors tend to pop, especially on light-colored fabrics.

- DTF: DTF prints are vibrant and durable, though the colors may not have the same depth as DTG prints, especially when dealing with fine gradients or intricate artwork.

Which Method is Best for Your Business?

Best for Small Businesses

DTG is often the better choice for businesses focusing on custom, one-off designs, or small orders. It allows for fast setup and high-quality results, perfect for customers seeking personalized designs.

Best for Scaling Up

DTF is a better option for larger-scale operations where cost-effectiveness and speed are crucial. Its low per-print cost and speed of production make it ideal for fulfilling bulk orders while maintaining good quality.

Conclusion

The decision between DTG and DTF depends largely on your business goals, target market, and production requirements. DTG is ideal for high-quality custom prints on cotton-based apparel with minimal setup time, making it perfect for smaller businesses. DTF, on the other hand, is the best option for high-volume, versatile printing, and can cater to a wider variety of materials at a lower per-print cost.

By evaluating your specific needs, you’ll be better positioned to make an informed choice between DTG and DTF printing, ensuring your clothing line runs efficiently and profitably. For businesses looking for a seamless print-on-demand solution, Apliiq offers a great platform to help you scale with custom apparel options and more. Learn more about Apliiq’s print-on-demand services here..